Product description

SCAFCO bucket elevators are built strong, reliable, and designed to be fast and efficient for all stages of material handling. SCAFCO guarantees that each system is designed and engineered to meet specific agricultural, commercial, and industrial requirements.

SCAFCO bucket elevators have corrosion-resistant G-115 (min. 350 gr/m2 zinc) galvanized coating, giving a durable, long lasting quality finish. Heavy-duty, crowned-face, double-disc drum pulley with static-conductive, oil resistant and fire retardant lagging is standard on all models.

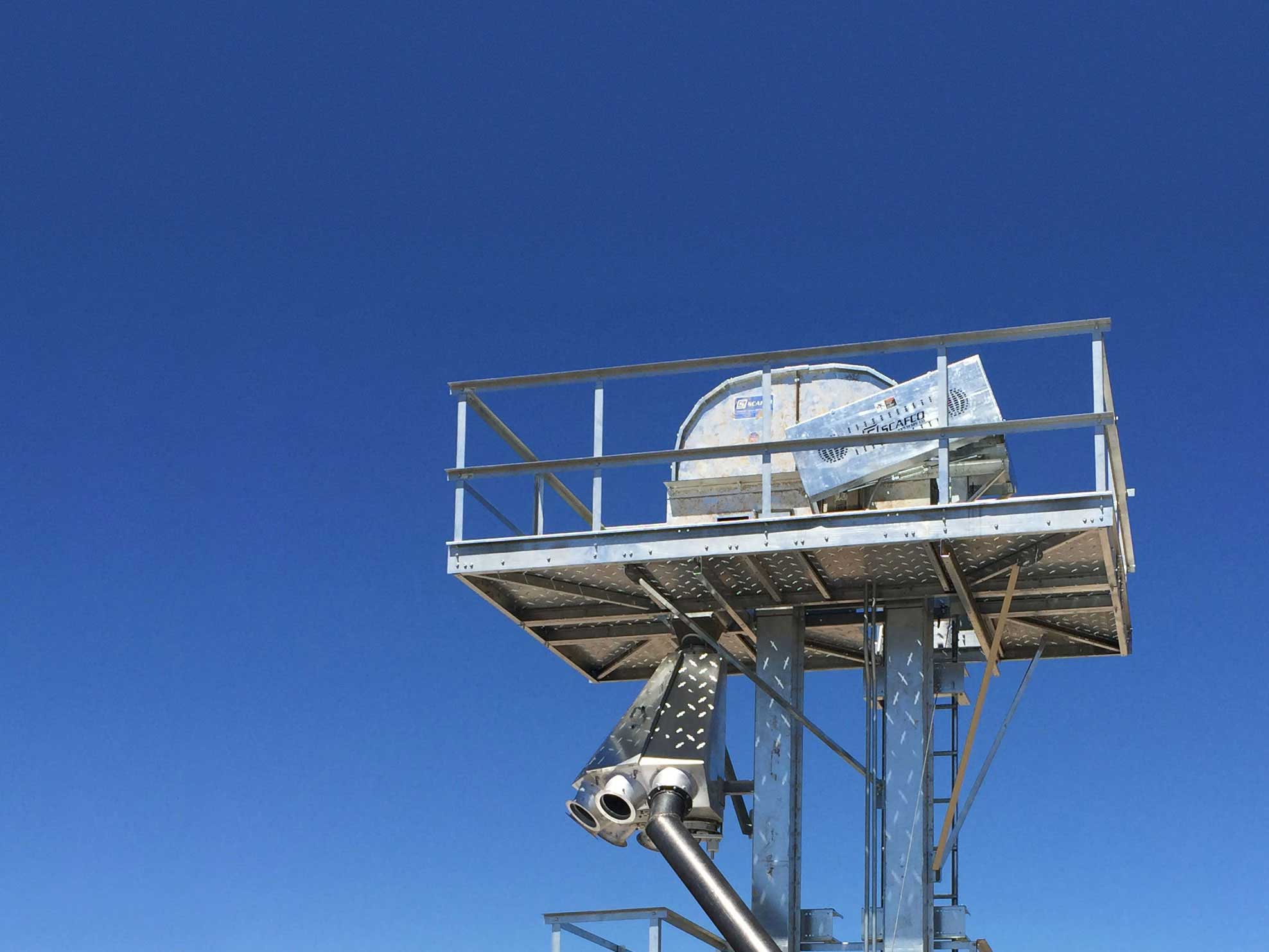

Bucket Elevator Heads

Elevator Heads

Two piece full-radius contoured hoods minimize wear, improve material discharge flow, and offer easy interior accessibility.

Platforms

Platforms are punched with a slip resistant pattern and feature a hatch that can be closed over the ladder access port. Built to OSHA safety standards, SCAFCO platforms provide easy access to the motor and drive.

Service Panels

SCAFCO elevator heads feature service panels on each side allowing for easy maintenance. These panels are weather-tight and flush to the inside.

Motors

Energy efficient motors are available for both domestic and international use.

brochure

Read our brochure to find out more information

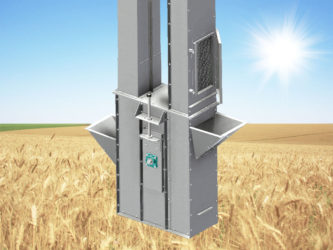

Trunking and Ladders

Engineered to be sturdy and strong, SCAFCO trunking will keep your bucket elevators standing tall for years to come. A unique bolt-together splice flange design provides rigidity and a weather tight seal.

Optional SCAFCO Bucket Elevator ladders are designed to be lightweight, easy to assemble and manufactured to meet OSHA safety standards.

Buckets

Buckets are constructed from a durable non-sparking polyethylene. Optional steel, nylon, or urethane buckets are also available.

Trunking

Trunk sections are connected using SCAFCO’s own unique splicing design, with no welding required.

Inspection Section

Field installed inspection sections can be located in four different configurations allowing for easy access and maintenance.

Elevator Ladders

Built to OSHA safety standards, SCAFCO ladders are sturdy and feature safety cages designed to improve climbing safety.

Features & Benefits

- Galvanized 14 gauge (1.83 mm) steel construction with bolt together seams prevent corrosion from moisture and dust accumulation

- Galvanized 12 gauge (2.59 mm) steel construction with bolt together seams prevent corrosion from moisture and dust accumulation on higher capacity (8,000 BPH/200 TPH) models and larger

- Maintenance friendly 5’ (1.52 m) inspection section with 4’ (1.22 m) removable panels at both front and back

- Guy cable brackets are standard to provide stability and maintain trunk alignment

- Bolted trunking with continuous sealant along flanges and splices Ladders feature 16” (406 mm) clear width galvanized slip-resistant rungs

- Rest platforms are provided for ladders at every 30’ (9.14 m) vertical rise

Elevator boots

SCAFCO Elevator boots are made of 11 gauge (3 mm) galvanized steel with bolted, angled vertical stiffeners and feature belt-tension take-up screws, utilizing corrosion-resistant ACME threaded rod. 7 gauge (4.55 mm) is standard on higher capacity models.

Flange Bearing

Externally mounted flange bearing provides material separation to prevent material contamination, lower operation temperatures, and provide easy access for maintenance and service.

Belt Tension Take-Up Screws

1” (25 mm) Acme threaded rod for maintaining belt tension and alignment.

Boot sections include:

- Externally mounted flange bearings

- Machined, full-length UHMW shaft seal at take-up plate bearing surface

- Heavy-duty, double-disc drum pulley

- Clean-out doors at each end

- Minimum 11 gauge (3.00 mm) galvanized steel with bolted, vertical stiffeners

Additional Bucket Elevator Options

- 12 Gauge (2.63 mm) trunk construction

- 10 Gauge (3.30 mm) trunk construction on higher capacity (8,000 BPH/200 TPH) models and larger

- ¼” (6 mm) expanded, metal-back urethane head housing and hood liners

- Head and distributor service platforms

- Ladder and safety cage with rest platforms

- Winged, self-cleaning boot pulley

- Flared boot hopper

- Standard boot hopper

- Down-leg boot inlet hopper

- Urethane-lined head discharge transitions

- Belt alignment and speed sensors

- Trunking pressure-relief vents

- Bolt-on shovel pocket (field installed)

related

Other Products

Water Tanks

SCAFCO designs and manufactures water tank systems in 11 different diameters (6′ to 36′) and…

Frac Sand Storage Bins

SCAFCO’s long history of success in the grain storage industry gives them the knowledge and…