News

A Stone Group of Companies employee spotted this SCAFCO Grain Systems Company hopper bottom bin on his recent trip to Idaho Falls.

Wood pellets, a valuable byproduct of Canada’s paper industry, need to be stored in a way that provides maximum protection from the elements. This producer in New Brunswick made the smart choice: They selected two SCAFCO Grain Systems Company hopper silos with letdown ladders and one silo on a custom load-out structure with a sifter on top.

SCAFCO elevators and incline chain conveyors are used to both load and unload these silos. This enables a receiving rate of 25 MTPH and a discharge rate of 100 MTPH. SCAFCO also provided elevator support towers at this site.

One of our Facebook followers sent us this photo of a pair of SCAFCO Grain Systems Company silos in Sumatra, Indonesia! At 30′ (9.14m) in diameter and 59’10” (18.24m) tall, they are also equipped with ladders, platforms, roof stairs, and aeration systems – a great system that is used for storing palm kernel!

If you think SCAFCO silos only store grain, think again! This Model 3950ES in Japan is used as an enclosure for industrial gas byproducts. Inside is an enormous bag that contains these gaseous materials. It is vital that they not escape, which is why the facility relied on SCAFCO’s precision engineering and experience with custom design.

This grain facility is one of seven 100,000-ton storage sites around Nigeria that SCAFCO Grain Systems Company supplied in 2009. It features 20 5,000MT silos, as well as SCAFCO hopper bottom silos for storing wet grain before drying. All silos are equipped with roof stairs, which help keep workers safe!

On a recent trip to Chile, SCAFCO Grain Systems Company’s Latin America Sales Manager Sandra Dixon snapped photos at a pair of corn storage facilities. They may look similar at first glance, but look closer: They actually differ substantially from one another!

This customer has a total storage capacity of 18,600 MT (732,400 bushels) of corn, including flat bottom and hopper bottom silos designed for Seismic Zone 4.

This customer also has mix of flat and hopper bottom silos, but with a total capacity of 5,650 MT (222,500 bushels). That bright Chilean sky, however, is just the same!

Proper aeration plays a key role in successful grain storage. Want to maximize your profits by optimizing your aeration system? SCAFCO Grain Systems Company’s article in this month’s edition of Milling and Grain magazine tells you how! Just turn to page 94 in the print or digital version.

These six 21’ diameter (6.4m), 62’9” tall (19.12m) 2112SHBTZ4 SCAFCO Grain Systems Company hopper bottom silos were designed to withstand the treacherous earthquakes of seismic zone 4. Each silo contains approximately 200 metric tons (14,033 bushels) of parchment coffee, which provides this Colombian producer with a total storage capacity of 1,200 metric tons (84,198 bushels).

The quality of SCAFCO Grain Systems Company products often attracts repeat customers. This is certainly the case with this grain trading company in Mexico, which has just installed its third SCAFCO silo. The first was installed in 2007 and the second in 2011. With the addition of this third silo, the customer’s grain storage capacity now stands at 15,000 metric tons (590,645 bushels).

At SCAFCO, nothing is more important than safety. That is why our new eave platform has begun shipping as standard equipment on all silos equipped with roof stairs.

Configurable for left-hand or right-hand entry, this eave platform mounts one ring below the roof hatch. It includes guard rails that fully enclose both the platform and the exterior ladder with safety cage. In addition to the platform itself, SCAFCO will also provide a standard access ladder. This ladder eliminates the need for workers to kneel on the roof stair when it becomes necessary to look inside the silo.

At SCAFCO, we always say that “nothing is more important than safety.” For proof that we take this philosophy seriously, look no further than our silo roof stairs. Where many of our competitors use roof cleats like those on the left, SCAFCO knows that when you are on top of a silo, more secure footing is always better. Roof cleats versus SCAFCO’s real roof stairs: It’s like comparing apples to oranges.

At SCAFCO, we always say that “nothing is more important than safety.” For proof that we take this philosophy seriously, look no further than our silo roof stairs. Where many of our competitors use roof cleats like those on the left, SCAFCO knows that when you are on top of a silo, more secure footing is always better. Roof cleats versus SCAFCO’s real roof stairs: It’s like comparing apples to oranges.

This month, we will all wish Larry a fond farewell as he retires from a truly remarkable career in the industry.

Larry has dedicated over half a century to the grain handling sector. When he started in 1968, customers were still uncertain as to whether or not metal structures could store grain effectively. His work helped show the industry that they could.

Over the years, Larry has worked in acquisitions, sales, training, and marketing for companies like Butler, Pascoe/York, MFS-Global, and GSI before coming to SCAFCO in 2004. He has traveled to over 60 countries.

At SCAFCO, Larry is known as a man who can always be relied upon to share his knowledge. He has contributed his ideas to many innovative marketing campaigns, and his creative use of language has kept readers of this newsletter informed and entertained for 153 consecutive issues.

In his retirement, Larry plans to continue his travels for leisure, rather than business. He will also continue to use his technological skills to digitize a lifetime of photographs.

Please join us in congratulating Larry on his well-earned retirement!

Regan Heaton, SCAFCO Grain Systems’ Sales Manager – USA/Canada received a video taken from a drone by a SCAFCO dealer who had put up these two 4836ES SCAFCO stiffened bins for walnut storage. “The bins have full floor aeration and SCAFCO supplied catwalk supports,” Regan reports. The catwalks and and conveyors were manufactured locally. These still images are taken from the drone video. Peak storage capacity is in the range of 71,200 FT3 (2,020M3).

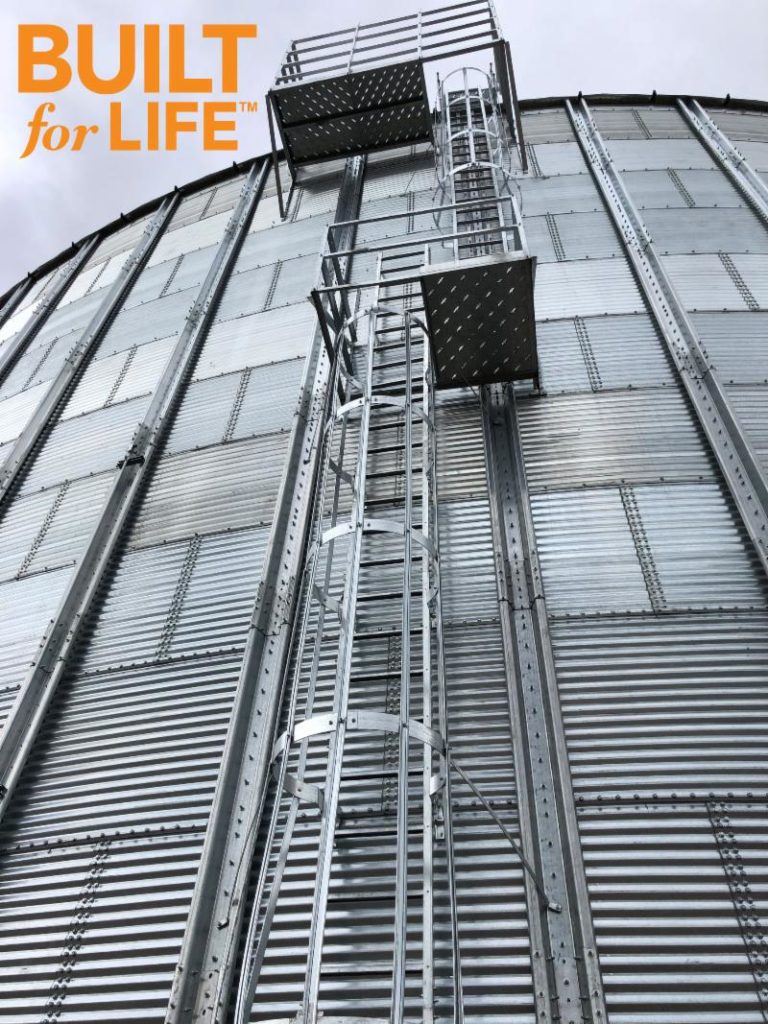

Sandra Dixon, SCAFCO Grain Systems’ Latin America Sales Manager, visited this construction site in Mexico of two (2) 10544ES silos. Sandra comments, ”I took the picture looking up at the SCAFCO ladder, safety cage, and safety rest platforms to show up close what is not so evident in a picture taken from far away. At SCAFCO, provision for safety is much more than words. Customer safety is engineered into our products.”

SCAFCO Grain Systems Company is glad to announce that we have released our updated Farm Bin Quoting Program!

The Farm Bin Quoting Program is a simple, web-based tool available to all U.S. farm dealers. The program allows dealers to provide quotes in the field, with selections for bin diameter, number of rings, and a power sweep unload option. Dealers can also enter a customer markup to print or email to their customers. With its straightforward dropdown format, the Farm Bin Quoting Program makes life easier for SCAFCO farm dealers and more convenient for their clients!